Today, let’s explore a thought-provoking concept that connects the investment philosophy of Charlie Munger with the practical use of stretch film. We’ll illustrate why not investing in a stretch film wrapping machine is like having a bucket with a hole, through the lens of a fictional company.

The Case of “RapidWrap Inc.”

Imagine a company named “RapidWrap Inc.,” which specializes in packaging a diverse range of products. Their challenge was significant: workers spent excessive hours manually wrapping products with stretch film rolls. This method was inefficient, slow, and physically taxing.

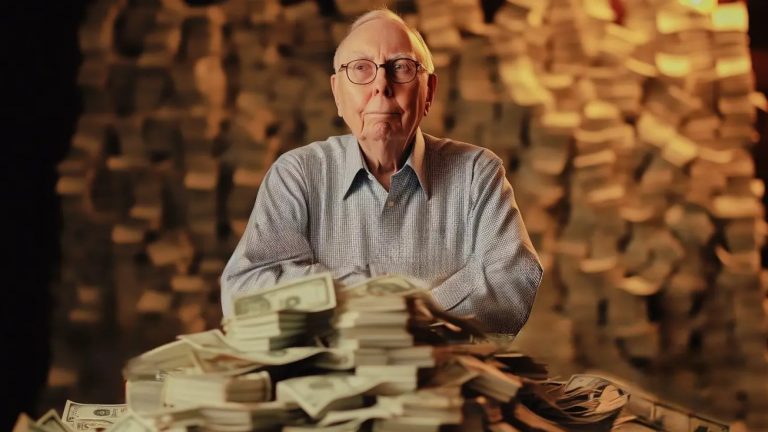

A Lesson from Charlie Munger

The change began when the general manager of RapidWrap Inc. attended an investment seminar and heard a quote from Charlie Munger: “The company that needs a new machine tool, and has not bought it yet, is already paying for it.” Initially, it seemed irrelevant, but soon the profoundness of these words struck home.

The Leaking Bucket Metaphor

The manager realized that manually wrapping products was akin to losing water from a bucket with a small hole. Not investing in a new, efficient bucket (in this case, a wrapping machine) to save money was actually more costly in the long run, in terms of lost time and resources.

The X1 Wrapping Machine: A Smart Investment

Inspired by Munger’s wisdom, the manager decided to invest in a cutting-edge stretch film wrapping machine. This machine revolutionized their wrapping process by being efficient, safe, and reliable, thereby conserving significant time and resources.

The economic benefits were substantial, with potential savings ranging from 20% to 60% when transitioning from manual to automated wrapping. These machines not only guarantee better wrapping, especially in crucial pallet areas, but also use stretch film more effectively than manual methods. They offer consistent wrap patterns and precise control over film use, leading to reduced waste and increased savings. Furthermore, while these machines might seem to replace manual labor, they actually benefit the workforce by eliminating physically demanding tasks, reducing the risk of injuries, and resulting in more satisfied employees.

Conclusion: Seal the Efficiency Gaps

The story of RapidWrap Inc. humorously yet insightfully reflects Charlie Munger’s wisdom. Avoiding necessary investments in tools or equipment can lead to unseen losses that accumulate over time. Just like a bucket losing water, a company not investing in appropriate technology can silently bleed money, time, and opportunities.

At Packsys, we provide a range of wrapping machines and other equipment to enhance your packaging processes, making them more economical and efficient. Let us help you close the gaps in your business’s efficiency and elevate your packaging operations to new heights.